What is the Recrystallization Process?

Recrystallization is an important phenomenon in materials science that involves the microstructural recovery of material after plastic deformation. This process is crucial for understanding material properties and optimizing processing techniques.

Mechanisms and Classification of Recrystallization

Recrystallization processes are typically triggered by heat treatment or thermal deformation and involve the natural recovery of materials after the generation of defects during deformation. Defects such as dislocations and grain boundaries promote the reduction of system-free energy at high temperatures through dislocation rearrangement and annihilation, leading to the formation of new grain structures.

Recrystallization can be classified into static recrystallization (SRX) and dynamic recrystallization (DRX). SRX occurs during annealing processes, while DRX takes place during thermal deformation. Furthermore, recrystallization can be further subdivided based on specific mechanisms, such as continuous dynamic recrystallization (CDRX), discontinuous dynamic recrystallization (DDRX), geometric dynamic recrystallization (GDRX), and metadynamic recrystallization (MDRX). These classifications are not strictly defined, and researchers may have different interpretations.

Factors influencing recrystallization

The recrystallization process is influenced by various factors, including the stacking fault energy (γSFE), initial grain size, thermal processing conditions, and second-phase particles. The magnitude of the stacking fault energy determines the dislocation breakdown and mobility, thereby affecting the recrystallization rate. Smaller initial grain sizes and suitable thermal processing conditions, such as high temperature and low strain rates, facilitate recrystallization. Second-phase particles can significantly influence the recrystallization process by hindering grain boundary motion.

Application of imaging techniques

EBSD and TEM are two classic imaging techniques used in recrystallization studies. EBSD analyzes the distribution and percentage of recrystallized grains using the DefRex map, although resolution limitations may pose accuracy issues. TEM, on the other hand, provides a direct observation of material substructures, such as dislocations, offering a more intuitive perspective for recrystallization studies.

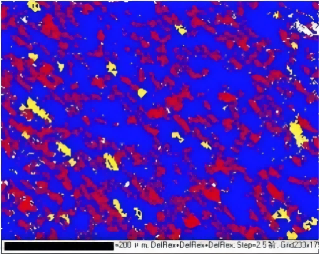

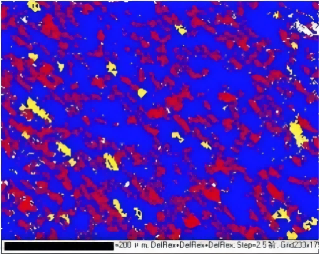

Application of EBSD in recrystallization studies

EBSD is used to determine whether grains have undergone recrystallization by observing grain boundaries. For example, in the DefRex maps of forged TNM alloys, grains surrounded by high-angle boundaries are typically considered recrystallized grains. This technique provides detailed information about grain orientations and grain boundary types, aiding in the understanding of microstructural changes during recrystallization.

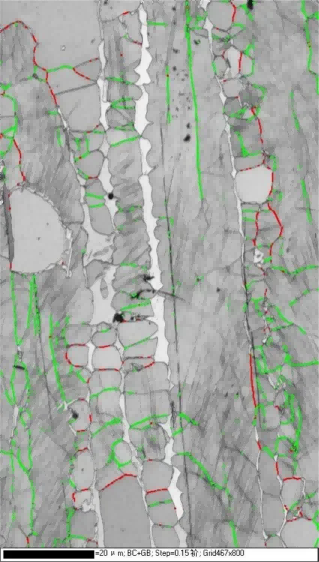

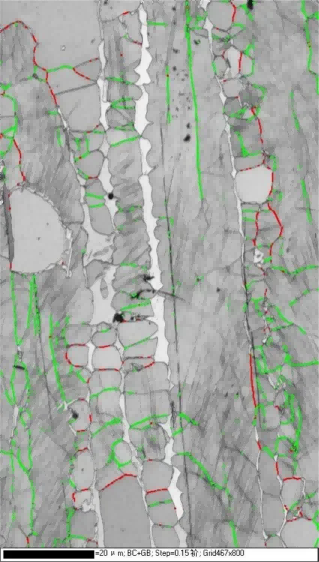

BC+GB (grain boundary) map of forged TiAl alloy

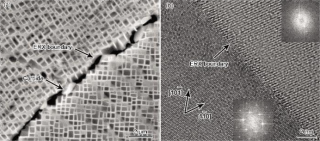

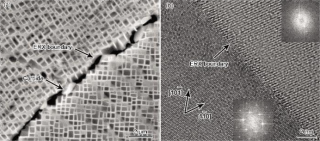

Application of TEM in recrystallization studies

TEM allows for more in-depth observations. For instance, in TEM images of rolled TiAl alloys, defect-free equiaxed grains, which are recrystallized grains, are clearly visible. This technique reveals the submicron-scale structures of materials, including dislocation arrangements and grain boundary characteristics, which are essential for understanding recrystallization mechanisms and optimizing material properties