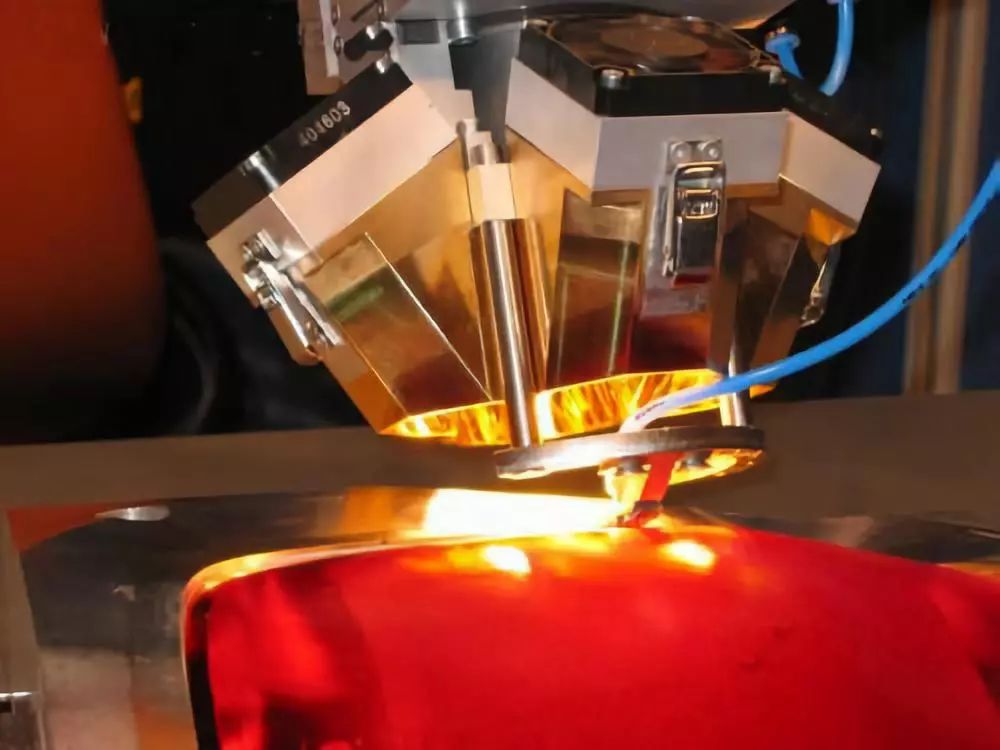

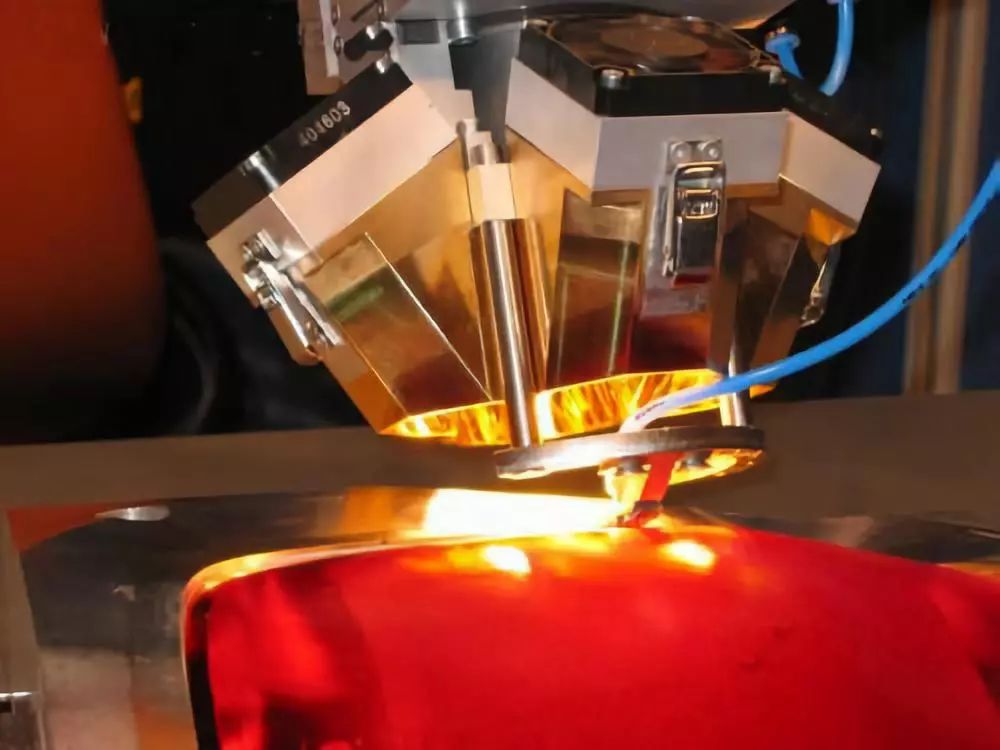

Laser welding is a welding method that uses a high-energy-density laser beam as a heat source, that is, laser radiation heats the surface of the workpiece, and the surface heat diffuses into the interior through heat conduction to melt the workpiece and form a specific molten pool. The laser beam passes through the upper layer of light-transmitting material, and then is absorbed by the lower layer material, and the laser energy is absorbed and converted into heat energy, since the two layers of materials are pressed together. Thermal energy is conducted from the absorbing layer to the light-transmitting layer, causing the two layers of material to melt and bond.

It can be seen that the energy of the laser beam must be absorbed by the plastic to achieve a good welding effect, so the CO2 laser is generally used for plastic laser welding. Also, not all plastics can be welded with laser welding. Plastics can be divided into thermoset and thermoplastic. Among them, thermosetting plastics are not reproducible and cannot be welded, while thermoplastics will melt after reheating (you can use heating and cooling to make them reversible), which is a so-called physical change, so it has weldability.

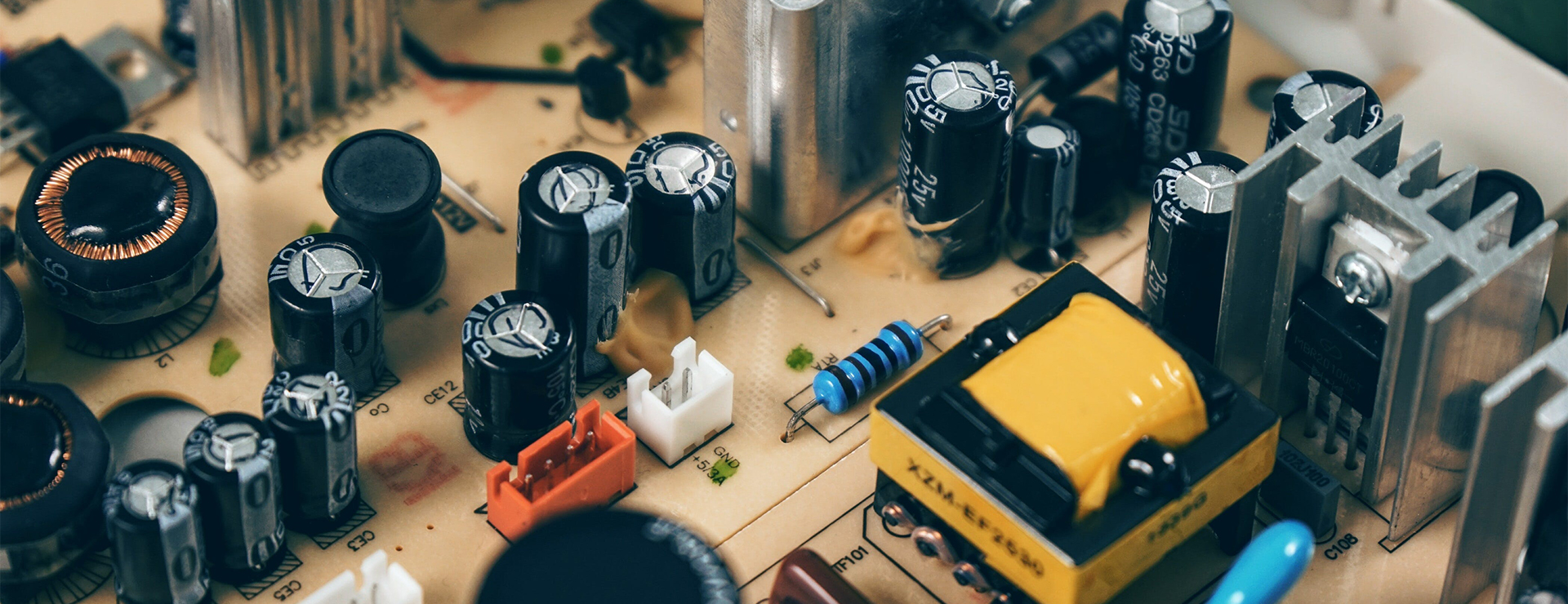

Compared with other welding methods, laser welding has the characteristics of high speed and good effect. way to weld complex parts, such as plastics containing circuit boards. Industries such as automotive, medical, consumer electronics, and food are ideal application areas for laser welding.

1. Automotive industry

Plastic laser welding machines are widely used in the automotive industry, such as automatic door locks, engine sensors, cab racks, fuel nozzles, gear shift racks, etc. Some models have also used laser welding for taillights.

2. Medical field

Plastic laser welding machines can be used to manufacture liquid storage tanks, liquid filtering equipment, hose connectors, ostomy bags, hearing aids, implants, microfluidic devices for analysis, and more.

3. Packaging industry

For example, the packaging of advanced industrial products, using plastic film welding technology, can obtain plastic packaging with high processing speed, reliable seams and beautiful appearance. Laser welding connection of plastic outer packaging material. Plastic materials are thermoplastics and elastomers.

Laser welding plastics has the comprehensive advantages of low cost, no pollution, high speed, convenient processing, easy realization of precise numerical control, wide application range of raw materials, good bonding and manufacturability. The application of plastic laser welding will become more and more extensive, and the technology will become more and more mature. In order to meet the growing demand for transparent plastic products in the industrial, medical and scientific research markets, Nanjing Hecho Technology provides various customized High-energy Transmission Optical Fiber for the laser plastic welding industry, with high transmittance, good uniformity, and high-energy transmission. Advantages, widely praised by the market.

Innovative features for a wide range of applications

Innovative features for a wide range of applications

The

The