The Ultimate Fan Controller Board Revolutionizing Your PC Cooling Experience

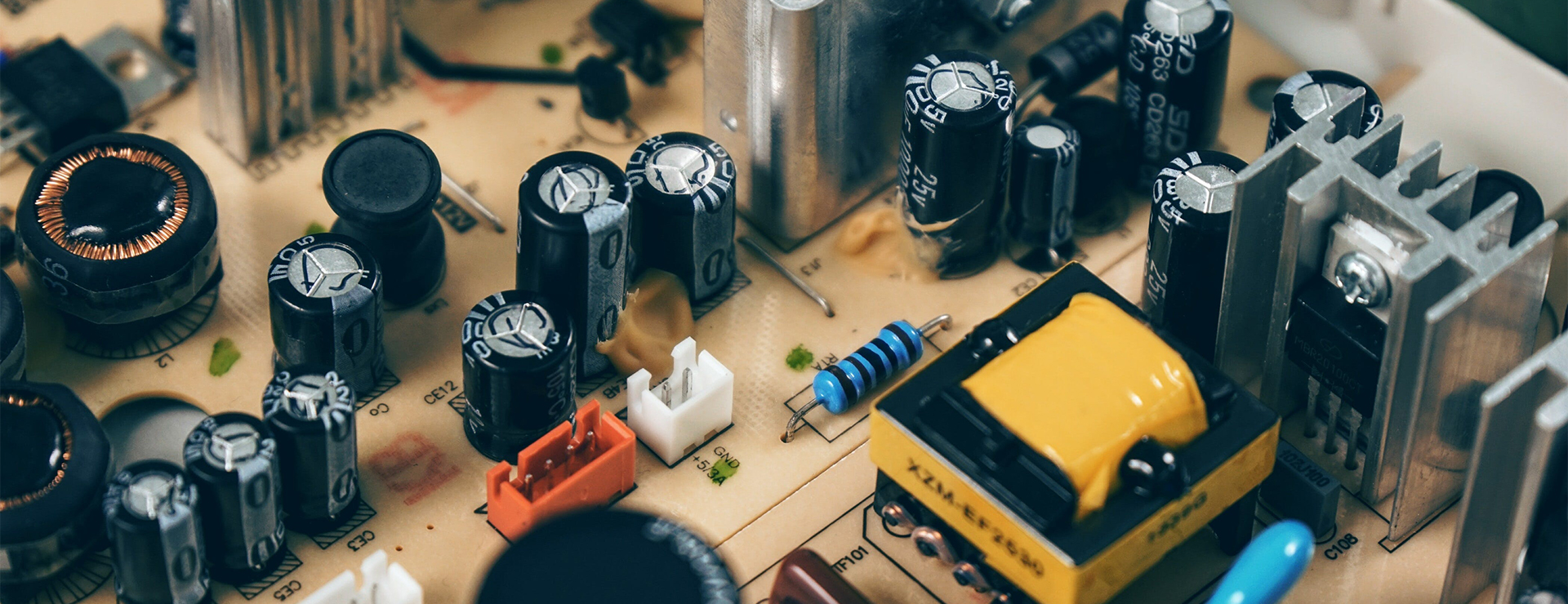

With the increasing demand for efficient cooling solutions in today’s fast-paced digital world, it’s crucial to have a reliable and versatile fan controller to keep your PC running optimally. At [Company Name], we take pride in offering cutting-edge fan PCBA controller and design services that cater to every customer’s unique needs.

Our fan PCBA controller is designed to provide precise control over your fan’s speed, ensuring optimal cooling performance while keeping noise levels at a minimum. With advanced features such as temperature sensing, automatic heat and cool electric fan assembly, and customizable settings, our digital fan controller takes your PC cooling to a whole new level.

One of our latest innovations is the state-of-the-art fan controller board designed specifically for table mode. This compact yet powerful PCB controller offers a seamless user experience, allowing you to effortlessly adjust fan speeds and monitor temperature levels directly from your desktop. Its sleek design and intuitive interface make it the perfect addition to any PC setup.

What sets our fan controller board apart is its unparalleled versatility. Our team of experts has carefully engineered it to be compatible with a wide range of fans, ensuring compatibility with different PC configurations. Whether you’re an avid gamer, a video editor, or a content creator, our fan controller board delivers exceptional cooling performance while enhancing the overall aesthetics of your PC.

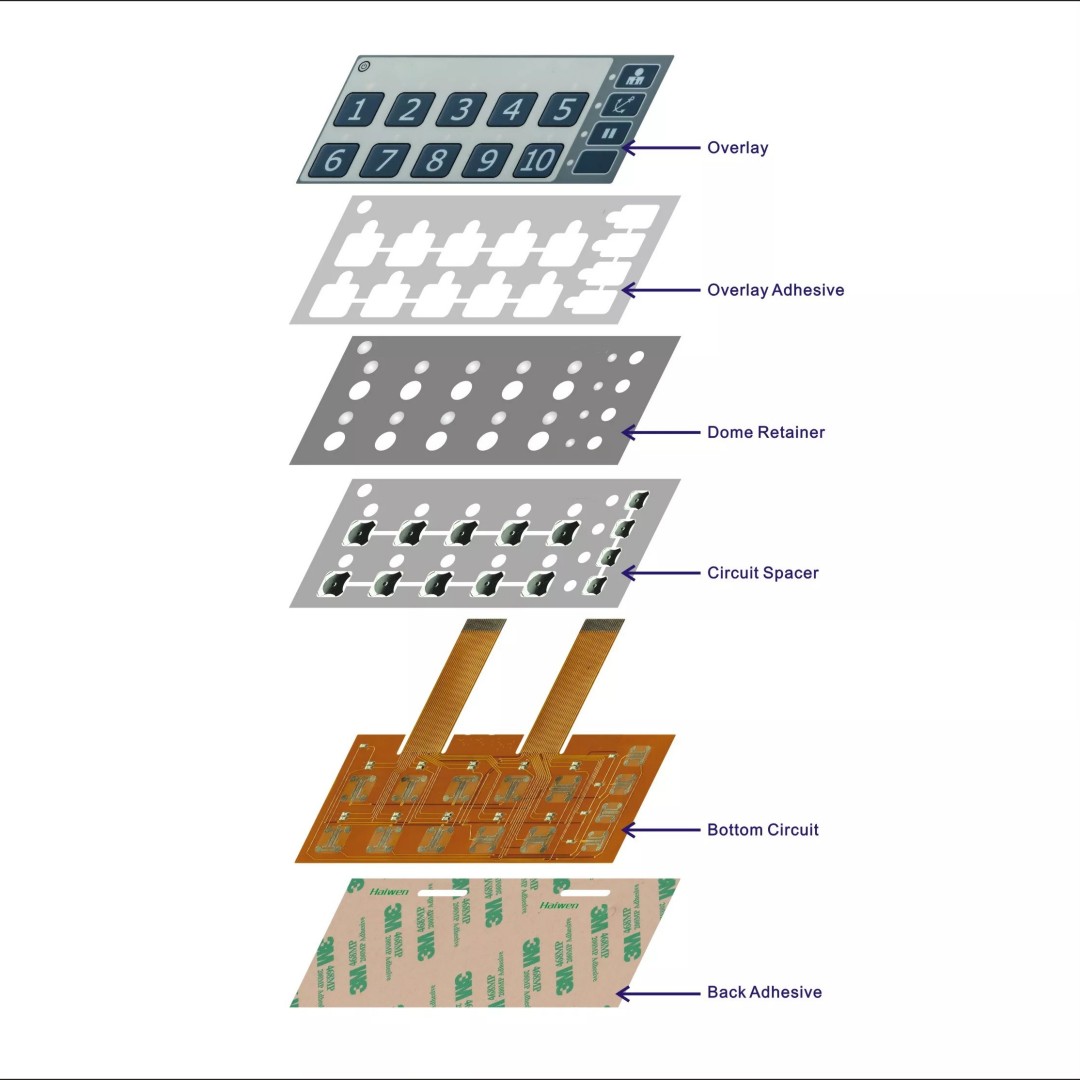

Our commitment to excellence doesn’t stop at providing top-notch products. We also offer fan PCBA design services, tailored to suit businesses and individuals seeking customized cooling solutions. Our experienced engineers collaborate closely with clients to understand their requirements and design a fan controller PCB that perfectly aligns with their specifications.

At [Company Name], we understand the importance of efficient and reliable cooling systems to safeguard your PC’s performance. That’s why we strive to deliver exceptional products and services, continuously pushing the boundaries of innovation in the cooling industry.

Invest in our cutting-edge fan PCBA controller and design services today, and experience a whole new level of precision, performance, and peace of mind. Stay cool even during the most intense tasks with our revolutionary fan controller board that exceeds expectations.

Contact us now to explore the possibilities and transform your PC cooling experience. Together, let’s take your cooling game to the next level!