Affordable CC2340R5 Bluetooth 5.3 Modules - In Stock Now

New CC2340R5 Bluetooth 5.3 Low Energy (BLE) modules are now in stock with four types -RF-BM-2340B1I, RF-BM-2340A2, RF-BM-2340A2I and RF-BM-2340C2. The alternative RF antennas and small different packages allow CC2340R5 modules to deliver industrial-grade performance, ultra-low-power consumption and robust connection for medical devices, building automation, consumer electronics, energy storage systems, and even vehicles.

Figure 1 New CC2340R5 Bluetooth LE Modules - Now in Stock

The introduction of these four items further extends the CC2340 series family, starting with the initial release of the CC2340R5 module RF-BM-2340B1 in 2023. In the marketing of RF-BM-2340B1 modules, they have gained recognition and favor among global customers and developers.

Why do they like the CC2340 series modules? Here are the key features and benefits, including:

Optimized 2.4GHz RF Transceiver

- Bluetooth Low Energy 5.3: 2M PHY, LE Coded PHY, BLE mesh, Direction Finding, HADM

- Proprietary 2.4GHz

- IEEE 802.15.4 ZigBee, Thread, Matter

Industrial-grade Performance

- TX power: up to + 8 dBm with temperature

- Industry-leading standby current: less than 710 nA

- RX sensitivity: -98 dBm @ 802.15.4 (2.4 GHz); -102 dBm @ 125 kbps Bluetooth (LE Coded PHY)

- Working temperature range: -40 °C ~ +85 °C

- 1.8V – 3.8V supply range

Rich Resources

- ARM Cortex-M0+ MCU @ 48MHz

- Up to 512KB of in-system programmable flash

- 36KB of ultra-low leakage SRAM

- Integrated Balun

- Supports over-the-air upgrade (OTA)

- Support peripherals including ADC, UART, SPI, I2C, RTC

- Channel sounding will be integrated with CC2340 modules soon.

User-Friendly Design

- Flexible RF output modes: PCB antenna, IPEX connector, Chip antenna, half-hole ANT RF pin

- Available dimension with stamp half-hole package: small, compact and mini sizes are optional.

Easy-to-Use Software and Tools

- BLE5.0 transparent transmission protocol (serial port transmission) with UART function: master-slave mode, slave mode, master mode, beacon mode.

- More AT commands: observer function with filter; UUID configuration; paring functions; automatic connection, etc.

- RF-star CC2340 series development board with USB-to-UART IC to support the tests and development.

- UART assistant: the powerful tool with strong practicability to assist in debugging and monitoring communication over serial ports.

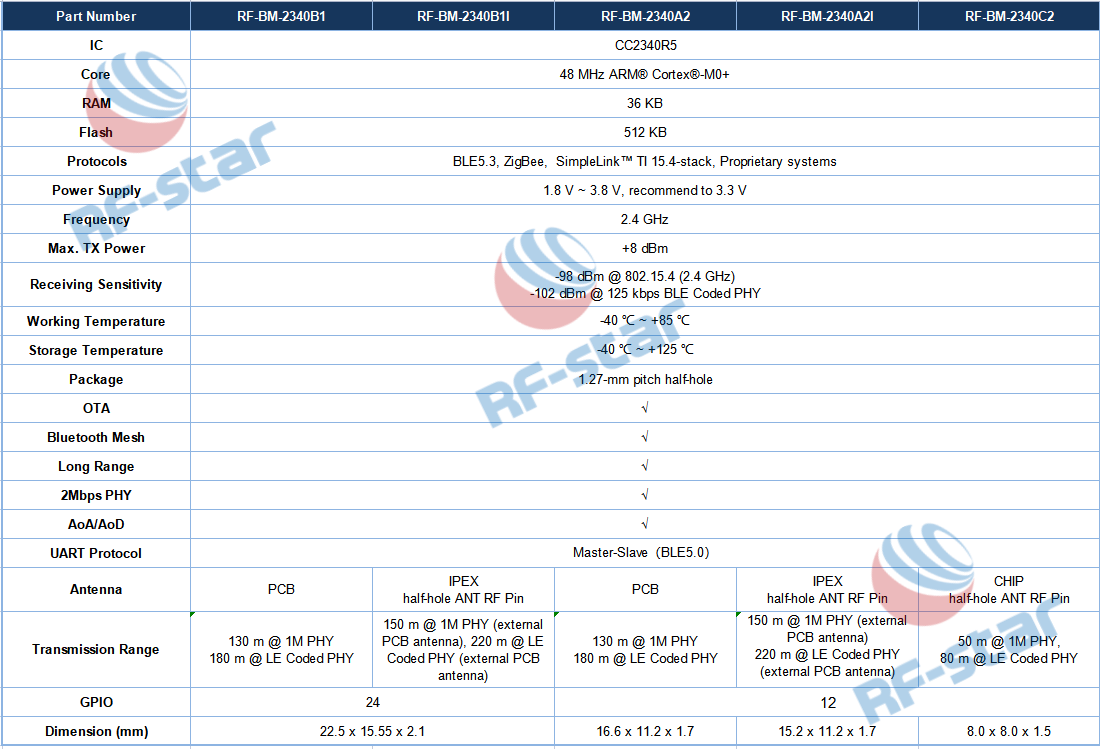

For more detailed differences among them, please check the below table of CC2340 Bluetooth LE modules.

Figure 2 Comparison Table of RF-star CC2340 Bluetooth LE Modules

Economical Wireless Solutions

Although the CC2340 modules boast numerous optimized features, their prices have not increased. On the contrary, to ensure widespread utility over varied industries, RF-star CC2340 modules are priced affordably, supporting budget-friendly purchases.

Hence, RF-star CC2340 series modules cater to multiple burgeoning fields by their versatility, such as:

- Medical Devices: The CC2340 modules' cost-effectiveness, low power consumption, and robust RF performance position them as an attractive choice for designs like CGMs (continuous glucose monitors), insulin pumps, blood glucose monitors, medical sensor patches and wearable fitness.

- Building Automation: The impressive output power of up to +8 dBm and multiprotocol including BLE 5.3, ZigBee 3.0, SimpleLink™TI 15.4-stack, and Proprietary systems make the RF modules perform well in wireless environmental sensors, fire safety systems, electronic smart lock, etc.

- Consumer Electronics: The small size of BLE modules enhances the aesthetics of the final products. The exceptionally low power consumption ensures prolonged and stable operation after one charge, while the affordable price adds an enticing allure for seamlessly integrating CC2340R5 modules into personal electronics, for example, keyboards and keypads, electronic and robotic toys, and smart trackers.

- Energy Storage: The imminent release of the Thread and Zigbee SDK, coupled with the existing BLE stack, will open up new possibilities for the energy storage industry. As a result, the CC2340R5 module serves as an ideal cost-effective wireless connectivity solution for EV chargers, Battery Management Systems (BMS), and microinverters.

Furthermore, the upcoming automotive-grade module RF-BM-2340QB1 based on the TI CC2340R5-Q1 chipset, meets the highest +125℃and AEC-Q100 standards and will be available soon.

For more information and inquiries, please visit rfstariot.com or contact us at info@szrfstar.com.

Explore further:

Similarities&Differences Between CC2340 Bluetooth LE modules

Introduction of CC2340 Series Ultra-Low Power BLE Module RF-BM-2340B1