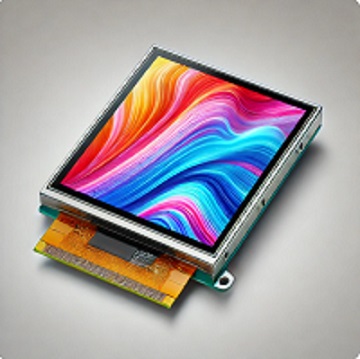

2.0 inch TFT LCD The Perfect Choice for Small Display Solution

When implementing small display products and devices, choosing the right display size is crucial. With its high resolution, wide viewing angle, fast response, and low power consumption, the 2.0 inch TFT LCD has become a popular choice for many projects.

Here let's take a detailed look at the characteristics of 2.0 inch TFT display and the 2.0 inch standard TFT module options offered for reference.

Features of 2.0 inch TFT LCD Display

Small Size

The 2.0 inch TFT LCD boasts a small size, making it ideal for various small devices. Whether for the control panel in smart homes or the small instruments in industrial control, the 2.0 inch size can easily fit in.

Exquisite Display Effect

Despite its small size, the 2.0 inch TFT LCD can achieve a high resolution like 320*240, providing clear and prominent image display.

Wide Viewing Angle

Most 2.0 inch TFT display possess full viewing angle, maintaining the stability of screen color and brightness at different angles. Users can enjoy a good visual experience no matter which angle they view the screen from.

Diverse Interface Options

The 2.0 inch TFT LCD offers a variety of interface options, including SPI, MCU, and parallel, meeting the needs of various applications.

Low Power Consumption

Due to its small size and limited display content, the power consumption of 2.0 inch TFT LCD is generally low, making it suitable for portable devices and low-power consumption applications.

2.0 inch Standard TFT Module options

To meet the needs of different customers, our company have designed multiple 2.0 inch TFT LCD standard models for customers. Below are some of our 2.0 inch TFT LCD standard models:

Landscape 2.0-inch TFT 320x240:

Part No.: FT-02044

Resolution: 320*240 dots

Viewing Direction: All

Interface: 16bit MCU

Driver IC: ILI9342E

Brightness: 250 cd/m²

This landscape 2.0 inch TFT LCD display is suitable for interactive display scenarios, offering a more refined and prominent viewing angle, bringing users a smoother operating experience.

Portrait 2.0-inch TFT LCD 240x320:

Part No.: FT-02015

Resolution: 240*320 dots

Viewing Direction: All

Interface: SPI

Driver IC: ST7789V

Brightness: 250 cd/m²

This portrait 2.0 inch TFT LCD display is ideal for monitoring shift modes and improving engineered display projects, providing users with a more professional display effect.

Portrait Mode 2.0-inch TFT LCD 240x296:

Part No.: FT-02024

Resolution: 240*296 dots

Viewing Direction: Full view

Interface: MCU

Driver IC: ST7789T3

Luminance: 600 cd/m²

Touch Screen: With touch

This special 2.0 inch touch display module features a unique 4 rounded-corner design, special resolution of 240*296, and high brightness of 600 cd/m², visible in sunlight. It is also integrated with CTP touchscreen, bringing users a more convenient user experience.

Applications

The 2.0 inch TFT LCD 320*240, with its excellent display effect and low power consumption, has been widely used in various fields. It can be seen in control panels of smart homes, small instruments in industrial control, display screens in medical equipment, and infotainment systems in automotive devices.

The 2.0 inch TFT LCD 240*296, with its unique rounded-corner design, high brightness, and CTP touch functionality, is an ideal choice for wearable products, providing users with a fashionable appearance and better display experience and functional support.

About Us

Guangdong Shengfeng Technology Co., Ltd., we are a full-industry-chain enterprise specializing in the research, design, production, and sales of monochrome LCD displays, color TFT LCD display modules, touch screens, and CG cover glasses.

We possess advanced production equipment and a professional research and development team, capable of providing customized mold opening services based on customer needs. We are committed to providing customers with industry-level specialized display products and services to meet their dual demands for speed and quality.

Shengfeng Technology, a manufacturer of LCD displays and intelligent display control solutions

"Display the world, touch the future.